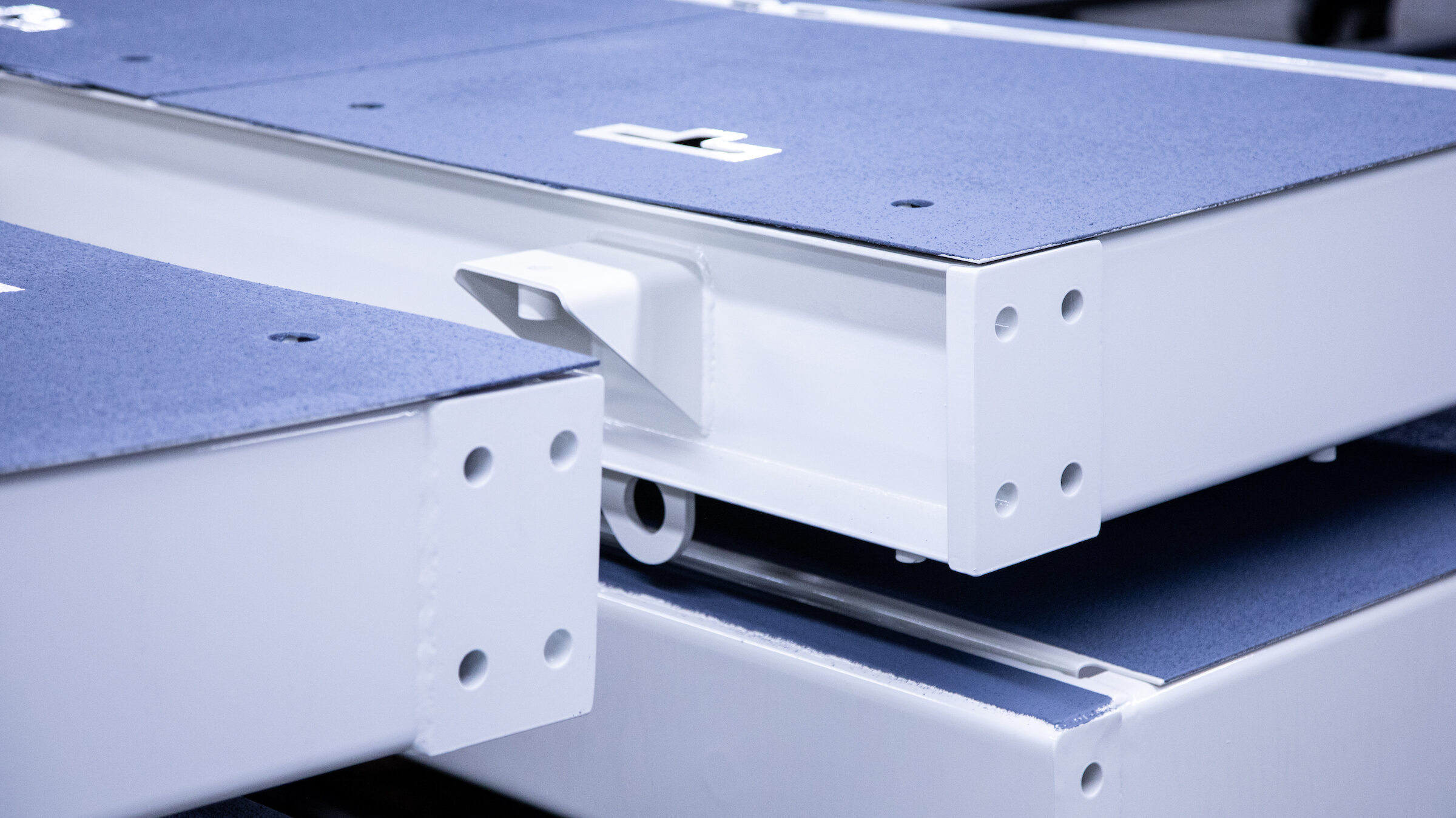

Paint, finish, & special surface conditions

Our finishing capabilities allow us to handle nearly your entire project — from fabrication to the end product.

Finishing capabilities

Painting

- 1 Paint Booth 24 ft x 40 ft.

- Airless Air Assisted.

- 5 Gallon Mixing Pot.

- 1 Quart Cup Guns for special mixes.

Plating

- Zinc Plating.

- Chrome.

- Anodizing

- Copper Flashing.

- Phosphate & Oil.

All done through local suppliers.

Heating Treating

All heating treating is done through outside suppliers. Certification test reports are provided and available to customers at their request.

Powder Coating

Powder coating is a “dry” painting process. Ground particles of pigment and resin are charged electrostatically and sprayed onto electrically grounded metal components. The charged particles, which adhere to the components, are heated in an oven which fuses the ‘’powder’’ to the surface. The baked finish is tough, attractive, durable, scratch-resistant, and high quality. Available in many colors and textures.

Part Size Max: 10ft Length x 8ft Wide x 5ft Tall